En 50288-7 Instrumentation Cable Collective Screen Armored PVC nga Paggamit sa Harsh Environment Collective Aluminum Foil Screens

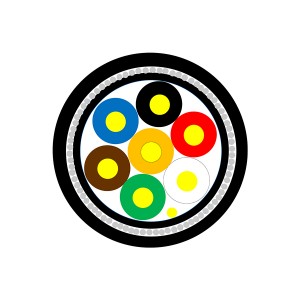

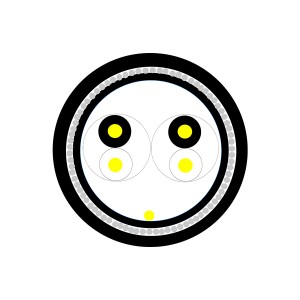

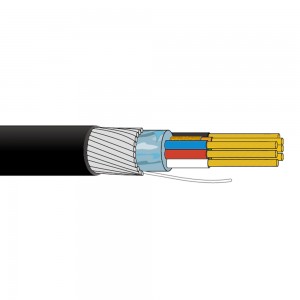

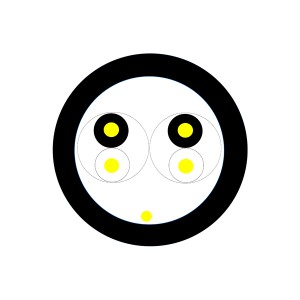

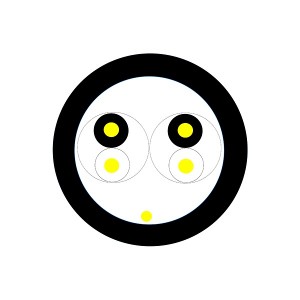

Pagtukod

Konduktor: Stranded Annealed Copper

Core insulation: XLPE, ibabaw sa MICA-tape wrapped conductor

Screen: OS Aluminum/PET + TC Drain wire • Inner sheath: LSZH, itom

Armour: Galvanized Steel Wire

Sa gawas nga sakoban: LSZH, itom

Mga Instruksyon sa Pag-instalar

Temperatura sa Pag-instalar: Labaw sa 0ºC

Operating Temperatura: -15ºC ~ 65ºC

Rated nga Boltahe: 90V, 300V, 500V

Test Boltahe (DC): 2000V Taliwala sa mga konduktor

2000V Taliwala sa Matag Konduktor ug Armor

Pagganap sa Elektrisidad

Min. Gibag-on sa Insulasyon

| Gidak-on sa konduktor (mm2) | Mini. Gibag-on (mm) | |||||

| Rated nga Boltahe | ||||||

| 90V | Dielectric nga Kusog | 300V | Dielectric nga Kusog | 500V | Dielectric nga Kusog | |

| 0.5 | 0.2 | ≥0.75KVac o ≥1.5KVdc | 0.26 | ≥1.0KVac o ≥2.0KVdc | 0.44 | ≥2.0KVac o ≥3.0KVdc |

| 0.75 | 0.2 | 0.26 | 0.44 | |||

| 1.0 | 0.26 | 0.26 | 0.44 | |||

| 1.5 | 0.3 | 0.35 | 0.44 | |||

Kinatibuk-ang Kinaiya

| Gidak-on sa konduktor (mm2) | Klase sa konduktor | Max. DCR (Ω/km) | Max. Mutual Capacitance Values pF/m | Max. Kapasidad Dili Balanse nga mga Pares/Quads Polyolefin (pF/500m) | Max.L/R Ratio (μH/Ω) | |

| Polyolefin (nf/km) | PVC (nf/km) | |||||

| 0.5 | 5 | 39.7 | 150 | 250 | 500 | 25 |

| 0.75 | 5 | 26.5 | 150 | 250 | 500 | 25 |

| 1.0 | 5 | 19.8 | 150 | 250 | 500 | 25 |

| 1.5 | 2 | 13.5 | 150 | 250 | 500 | 40 |

90V, Multi-pair, PE Insulated, Kinatibuk-ang Screened

| Numero sa mga Pares | Konduktor | Gibag-on sa Insulasyon (mm) | Gi-screen | Gibag-on sa Sheath (mm) | Kinatibuk-ang Diametro (mm) | |

| Gidak-on (mm2) | Klase | |||||

| 1 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.6 | 4.5 |

| 2 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.7 | 6.9 |

| 3 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.7 | 7.5 |

| 4 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.8 | 8.3 |

| 5 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.8 | 9.1 |

| 6 | 0.5 | 2, 5 | 0.35 | Al-foil | 0.9 | 10.1 |

| 8 | 0.5 | 2, 5 | 0.35 | Al-foil | 1 | 11.5 |

| 10 | 0.5 | 2, 5 | 0.35 | Al-foil | 1.1 | 13.2 |

| 1 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.7 | 5.3 |

| 2 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.8 | 7.8 |

| 3 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.8 | 8.3 |

| 4 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.9 | 9.3 |

| 5 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.9 | 10 |

| 6 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 1 | 11.1 |

| 8 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 1 | 12.3 |

| 10 | 0.5 | 2, 5 | 0.35 | Al-foil + TC Braided | 1.1 | 14 |

| 1 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.6 | 4.9 |

| 2 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.7 | 7.6 |

| 3 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.7 | 8.2 |

| 4 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.8 | 9.1 |

| 5 | 0.75 | 2, 5 | 0.35 | Al-foil | 0.9 | 10.2 |

| 6 | 0.75 | 2, 5 | 0.35 | Al-foil | 1 | 11.3 |

| 8 | 0.75 | 2, 5 | 0.35 | Al-foil | 1.1 | 12.4 |

| 10 | 0.75 | 2, 5 | 0.35 | Al-foil | 1.2 | 14.8 |

| 1 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.7 | 5.7 |

| 2 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.8 | 8.4 |

| 3 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.9 | 9.4 |

| 4 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 0.9 | 10.1 |

| 5 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 1 | 11.2 |

| 6 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 1 | 12.1 |

| 8 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 1.1 | 13.7 |

| 10 | 0.75 | 2, 5 | 0.35 | Al-foil + TC Braided | 1.2 | 15.5 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil | 0.6 | 5.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.9 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil | 0.9 | 9.8 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 10.7 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 11.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil | 1.1 | 13 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil | 1.2 | 14.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil | 1.3 | 17 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.8 | 6.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 9.8 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 10.6 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1 | 11.5 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.1 | 12.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.2 | 14 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.3 | 15.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.3 | 17.8 |

| 1 | 1.5 | 2, 5 | 0.45 | Al-foil | 0.7 | 6.5 |

| 2 | 1.5 | 2, 5 | 0.45 | Al-foil | 0.9 | 10.4 |

| 3 | 1.5 | 2, 5 | 0.45 | Al-foil | 1 | 11.5 |

| 4 | 1.5 | 2, 5 | 0.45 | Al-foil | 1 | 12.4 |

| 5 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.1 | 13.8 |

| 6 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.2 | 15.3 |

| 8 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.3 | 17.4 |

| 10 | 1.5 | 2, 5 | 0.45 | Al-foil | 1.4 | 19.9 |

| 1 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 0.8 | 7.3 |

| 2 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1 | 11.4 |

| 3 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1 | 12.3 |

| 4 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1.1 | 13.4 |

| 5 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1.2 | 14.8 |

| 6 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1.3 | 16.3 |

| 8 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1.4 | 18.4 |

| 10 | 1.5 | 2, 5 | 0.45 | Al-foil + TC Braided | 1.4 | 20.7 |

300V, Multi-pair, PE Insulated, Kinatibuk-ang Screened

| Numero sa mga Pares | Konduktor | Gibag-on sa Insulasyon (mm) | Gi-screen | Gibag-on sa Sheath (mm) | Kinatibuk-ang Diametro (mm) | |

| Gidak-on (mm2) | Klase | |||||

| 1 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.6 | 4.7 |

| 2 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.7 | 7.3 |

| 3 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.1 |

| 4 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.7 |

| 5 | 0.5 | 2, 5 | 0.4 | Al-foil | 0.9 | 9.7 |

| 6 | 0.5 | 2, 5 | 0.4 | Al-foil | 1 | 10.8 |

| 8 | 0.5 | 2, 5 | 0.4 | Al-foil | 1 | 12.1 |

| 10 | 0.5 | 2, 5 | 0.4 | Al-foil | 1.1 | 13.9 |

| 1 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.7 | 5.5 |

| 2 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.8 | 8.1 |

| 3 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.8 | 8.7 |

| 4 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 9.7 |

| 5 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 1 | 10.7 |

| 6 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 1 | 11.6 |

| 8 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.1 | 13.1 |

| 10 | 0.5 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.2 | 14.9 |

| 1 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.6 | 5.3 |

| 2 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.7 | 8.3 |

| 3 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.8 | 9.2 |

| 4 | 0.75 | 2, 5 | 0.4 | Al-foil | 0.9 | 10.1 |

| 5 | 0.75 | 2, 5 | 0.4 | Al-foil | 1 | 11.3 |

| 6 | 0.75 | 2, 5 | 0.4 | Al-foil | 1 | 12.3 |

| 8 | 0.75 | 2, 5 | 0.4 | Al-foil | 1.1 | 14 |

| 10 | 0.75 | 2, 5 | 0.4 | Al-foil | 1.2 | 16.1 |

| 1 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.8 | 7.5 |

| 2 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.8 | 9.3 |

| 3 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 10.2 |

| 4 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 11.1 |

| 5 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 1 | 12.1 |

| 6 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.1 | 13.3 |

| 8 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.2 | 15 |

| 10 | 0.75 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.3 | 17.1 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil | 0.6 | 5.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil | 0.8 | 8.9 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil | 0.9 | 9.8 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 10.7 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil | 1 | 11.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil | 1.1 | 13 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil | 1.2 | 14.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil | 1.3 | 17 |

| 1 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.8 | 6.5 |

| 2 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 9.8 |

| 3 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 0.9 | 10.6 |

| 4 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1 | 11.5 |

| 5 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.1 | 12.7 |

| 6 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.2 | 14 |

| 8 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.3 | 15.8 |

| 10 | 1 | 2, 5 | 0.4 | Al-foil + TC Braided | 1.3 | 17.8 |

| 1 | 1.5 | 2, 5 | 0.5 | Al-foil | 0.7 | 6.7 |

| 2 | 1.5 | 2, 5 | 0.5 | Al-foil | 1 | 11 |

| 3 | 1.5 | 2, 5 | 0.5 | Al-foil | 1 | 11.8 |

| 4 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.1 | 13 |

| 5 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.2 | 14.4 |

| 6 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.3 | 16 |

| 8 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.4 | 18.2 |

| 10 | 1.5 | 2, 5 | 0.5 | Al-foil | 1.4 | 20.6 |

| 1 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 0.8 | 7.5 |

| 2 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1 | 11.8 |

| 3 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1.1 | 12.8 |

| 4 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1.2 | 14 |

| 5 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1.2 | 15.2 |

| 6 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1.3 | 16.8 |

| 8 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1.4 | 19 |

| 10 | 1.5 | 2, 5 | 0.5 | Al-foil + TC Braided | 1.4 | 21.4 |

500V, Multi-pair, PE Insulated, Kinatibuk-ang Screened

| Numero sa mga Pares | Konduktor | Gibag-on sa Insulasyon (mm) | Gi-screen | Gibag-on sa Sheath (mm) | Kinatibuk-ang Diametro (mm) | |

| Gidak-on (mm2) | Klase | |||||

| 1 | 0.5 | 2, 5 | 0.6 | Al-foil | 0.6 | 5.5 |

| 2 | 0.5 | 2, 5 | 0.6 | Al-foil | 0.8 | 8.9 |

| 3 | 0.5 | 2, 5 | 0.6 | Al-foil | 0.9 | 9.8 |

| 4 | 0.5 | 2, 5 | 0.6 | Al-foil | 1 | 10.7 |

| 5 | 0.5 | 2, 5 | 0.6 | Al-foil | 1 | 11.7 |

| 6 | 0.5 | 2, 5 | 0.6 | Al-foil | 1.1 | 13 |

| 8 | 0.5 | 2, 5 | 0.6 | Al-foil | 1.2 | 14.8 |

| 10 | 0.5 | 2, 5 | 0.6 | Al-foil | 1.3 | 17 |

| 1 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 0.8 | 6.5 |

| 2 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 0.9 | 9.8 |

| 3 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 0.9 | 10.6 |

| 4 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 11.5 |

| 5 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.1 | 12.7 |

| 6 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.2 | 14 |

| 8 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.3 | 15.8 |

| 10 | 0.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.3 | 17.8 |

| 1 | 0.75 | 2, 5 | 0.6 | Al-foil | 0.7 | 6.1 |

| 2 | 0.75 | 2, 5 | 0.6 | Al-foil | 0.9 | 9.7 |

| 3 | 0.75 | 2, 5 | 0.6 | Al-foil | 0.9 | 10.5 |

| 4 | 0.75 | 2, 5 | 0.6 | Al-foil | 1 | 11.6 |

| 5 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.1 | 12.9 |

| 6 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.2 | 14.2 |

| 8 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.3 | 16.2 |

| 10 | 0.75 | 2, 5 | 0.6 | Al-foil | 1.3 | 18.4 |

| 1 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 0.8 | 6.9 |

| 2 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 10.7 |

| 3 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 11.5 |

| 4 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 12.4 |

| 5 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.1 | 13.7 |

| 6 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.2 | 15 |

| 8 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.3 | 17 |

| 10 | 0.75 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.4 | 19.4 |

| 1 | 1 | 2, 5 | 0.6 | Al-foil | 0.7 | 6.5 |

| 2 | 1 | 2, 5 | 0.6 | Al-foil | 0.9 | 10.4 |

| 3 | 1 | 2, 5 | 0.6 | Al-foil | 1 | 11.5 |

| 4 | 1 | 2, 5 | 0.6 | Al-foil | 1 | 12.4 |

| 5 | 1 | 2, 5 | 0.6 | Al-foil | 1.1 | 13.8 |

| 6 | 1 | 2, 5 | 0.6 | Al-foil | 1.2 | 15.3 |

| 8 | 1 | 2, 5 | 0.6 | Al-foil | 1.3 | 17.4 |

| 10 | 1 | 2, 5 | 0.6 | Al-foil | 1.4 | 19.9 |

| 1 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 0.8 | 7.3 |

| 2 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 11.4 |

| 3 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 12.3 |

| 4 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.1 | 13.4 |

| 5 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.2 | 14.8 |

| 6 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.3 | 16.3 |

| 8 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.4 | 18.4 |

| 10 | 1 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.4 | 20.7 |

| 1 | 1.5 | 2, 5 | 0.6 | Al-foil | 0.8 | 7.3 |

| 2 | 1.5 | 2, 5 | 0.6 | Al-foil | 1 | 11.6 |

| 3 | 1.5 | 2, 5 | 0.6 | Al-foil | 1 | 12.6 |

| 4 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.1 | 13.8 |

| 5 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.2 | 15.4 |

| 6 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.3 | 17 |

| 8 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.4 | 19.3 |

| 10 | 1.5 | 2, 5 | 0.6 | Al-foil | 1.4 | 22 |

| 1 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 0.8 | 7.9 |

| 2 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1 | 12.6 |

| 3 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.1 | 13.6 |

| 4 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.2 | 14.8 |

| 5 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.2 | 16.4 |

| 6 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.3 | 17.8 |

| 8 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.4 | 20.1 |

| 10 | 1.5 | 2, 5 | 0.6 | Al-foil + TC Braided | 1.4 | 22.7 |

Isulat ang imong mensahe dinhi ug ipadala kini kanamo